Structural Steel Does Not Warp, Wilt, Distort or Bend Radically Without Cracking or Shattering … unless superheated

The Science Behind Steel: Strength, Flexibility, and the Role of Heat

Steel, a cornerstone of modern infrastructure, owes its remarkable properties to its unique composition and the precise methods employed in its manufacturing. Understanding the strength and flexibility of steel, and the crucial role of heat in achieving these properties, sheds light on why it is an indispensable material in construction, engineering, and various other industries.

The Strength of Structural Steel

Structural steel is revered for its high tensile strength, ductility, and toughness. These characteristics enable it to withstand immense forces without breaking or deforming. The strength of steel arises from its microstructure, which is primarily composed of iron and carbon. The carbon content, typically ranging from 0.2% to 2.1%, enhances the hardness and strength of the steel by preventing dislocation movements within the iron crystal lattice.

Structural steel is designed to support heavy loads and resist bending and warping under stress. This strength is achieved through a combination of alloying elements and heat treatments that refine the grain structure and enhance its mechanical properties. The result is a material that can endure extreme conditions and provide the stability required for buildings, bridges, and other critical structures.

The Inability of Steel to Warp Without Cracking

Despite its strength, steel in its natural, unheated state is brittle when subjected to certain types of stress. Attempting to bend, warp, or fold steel along multiple axes without applying sufficient heat can lead to cracks or even shattering. This brittleness occurs because the crystal lattice of the steel cannot accommodate the deformation, causing the atomic bonds to break.

When steel is bent or deformed without heat, the internal stresses exceed the material’s yield strength, leading to the formation of micro-cracks that propagate through the structure. These cracks weaken the steel, making it prone to catastrophic failure under further stress. Therefore, manipulating steel requires careful control of temperature to prevent damage and maintain its integrity.

The Role of Heat in Manipulating Steel

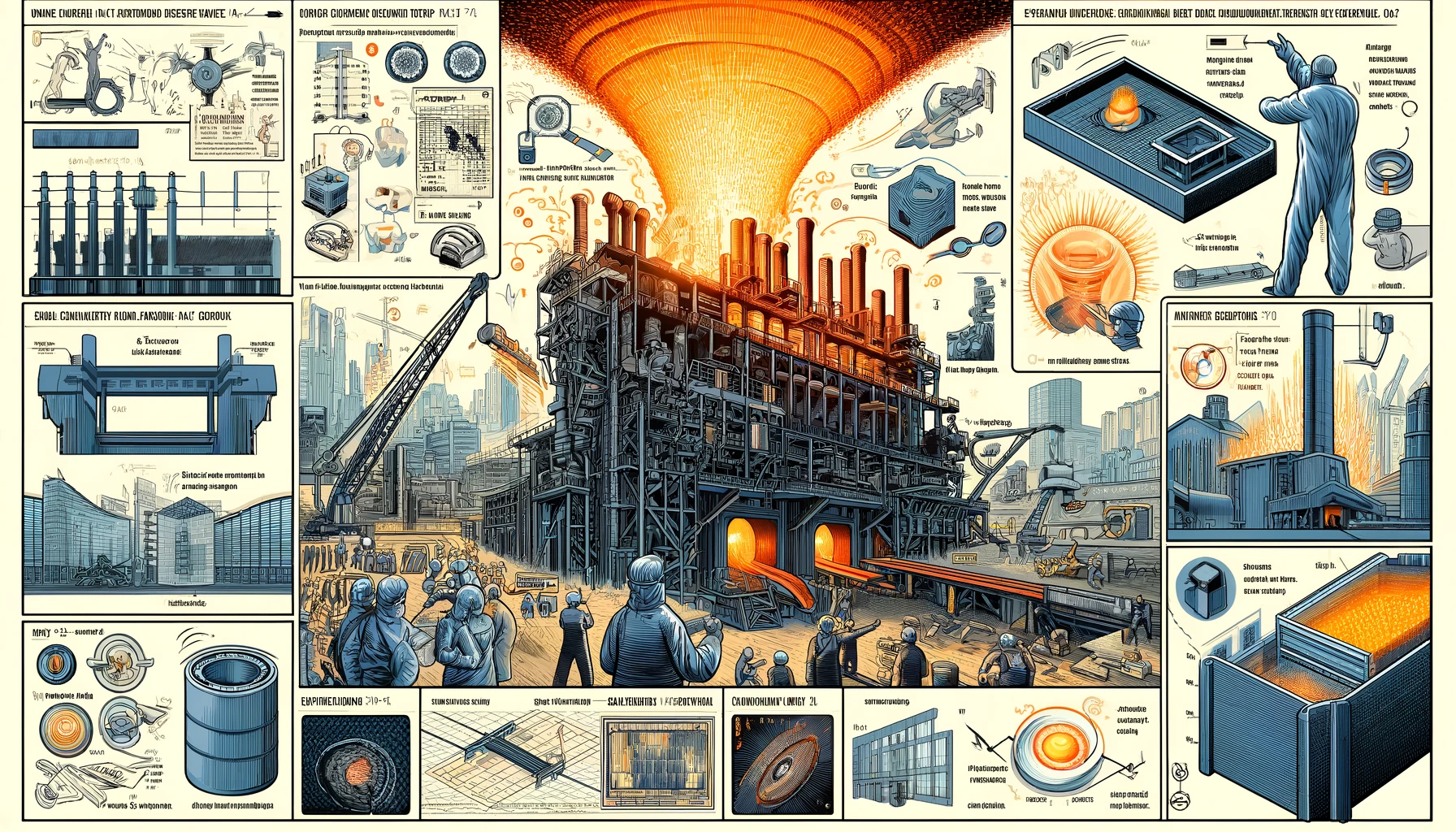

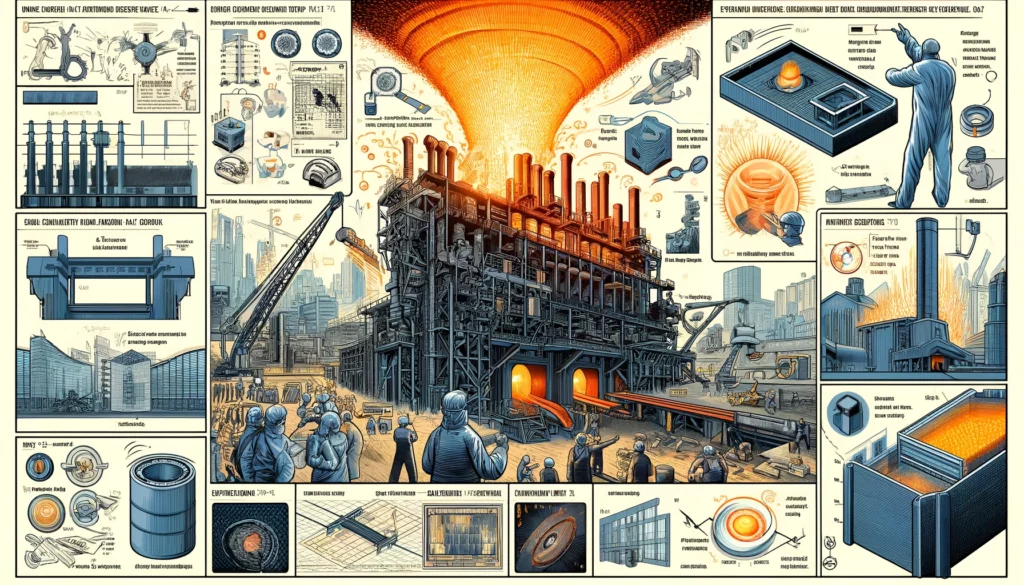

To bend or fold steel without cracking or shattering, it must be heated to high temperatures, typically achieved in a blast furnace. The blast furnace generates temperatures in excess of 1,500°C (2,732°F), sufficient to make steel pliable. This heat allows the steel’s crystal lattice to become more flexible, enabling it to deform without breaking.

When heated to these high temperatures, the steel undergoes a phase transformation, becoming more ductile. This ductility allows the steel to be bent along multiple axes and folded back over itself without developing cracks. The heat reduces the yield strength and increases the plasticity of the steel, allowing for intricate shaping and molding.

Once the desired shape is achieved, the steel is gradually cooled and may undergo additional heat treatments, such as quenching and tempering, to restore its strength and hardness. These processes refine the grain structure and enhance the mechanical properties, ensuring that the steel retains its form and function.

Superheating and Advanced Energy Applications

In addition to traditional methods, superheating steel through the application of other energy sources can also facilitate incredible, crack-free bends. Techniques such as induction heating, laser heating, and plasma arcs provide controlled, localized heating that allows for precise manipulation of the steel.

- Induction Heating: This method uses electromagnetic fields to generate heat within the steel, allowing for rapid and localized heating. Induction heating is efficient and can be precisely controlled, making it ideal for bending steel without causing damage.

- Laser Heating: High-powered lasers can focus intense heat on specific areas of the steel, enabling precise cuts and bends. This method minimizes the heat-affected zone and reduces the risk of cracking.

- Plasma Arcs: Plasma arcs produce extremely high temperatures, capable of melting and reshaping steel. This method is particularly useful for applications requiring high precision and minimal material distortion.

These advanced heating techniques offer new possibilities for manipulating steel, enhancing its versatility and expanding its applications in various industries.

Conclusion

The strength and flexibility of steel are a testament to its engineering marvel. Understanding the crucial role of heat in manipulating steel without compromising its integrity underscores the importance of precise temperature control in metallurgy. Whether through traditional blast furnaces or advanced superheating techniques, the ability to bend and shape steel without cracking opens new avenues for innovation and excellence in construction and manufacturing.