“The Baltimore Francis Scott Key Bridge take-down was a trillion-dollar costly event, ongoing, and yet all culpable persons remain unnamed, kept totally anonymous, with some reportedly having been slyly ‘escaped’ from the country! There is, in fact, zero publicly-verifiable evidence that any genuine Captain, Pilots or Crew ever existed: Was DALI a remote-controlled ghost-ship on kamikazee mission from its outset? No waves or creaking metal nor splash-down sounds at all were recorded nor (initially) noted by any (reportedly) nearby persons; cameras recorded zero shaking, seismometers measured zero vibration. Anomalies and oddities galore overwhelm the aftermath, beguile reason, confound explanation. No interviews exist with supposed survivors; “family and friends” etc interviews reveal ‘dupers-delight’ micro-facial-expressions with other hallmarks suggestive of fraud. No verifications of any supposed deaths have yet been publicized. Rampant is the extremely suspicious damage with blatantly visible, verifiable anomalies (including massive, five-storys tall fireballs in both original night-time videos) totally inexplicable (and wholly ignored) by official theory or story. Grand payola galore is already underway with loads more coming. This event appears to involve another shabby yet audacious crime, militarized from gov to salvage to rebuild. There was no rescue skiff on scene as required by OSHA. No horn blasts from ship warned of imminent collision. The DALI ship departed despite (supposed) dire electrical problems, illegal at any time and even more highly unusual in the cold, dark night-time (part #94, first ‘after-sundown departure’ in two years). It goes on and on and on. Criminal was this manufactured event, through and through, and that’s before considering the absurd number of other anomalies ignored by the complicit, owned, ‘kept-pet’ mass-media…”

Part #91 adapted from a video comment.

Don’t miss the apparent precursor Tampa Bay Sunshine Skyway Bridge take-down test-run in 1981.

Index . Oddity List . Official Story . Summary

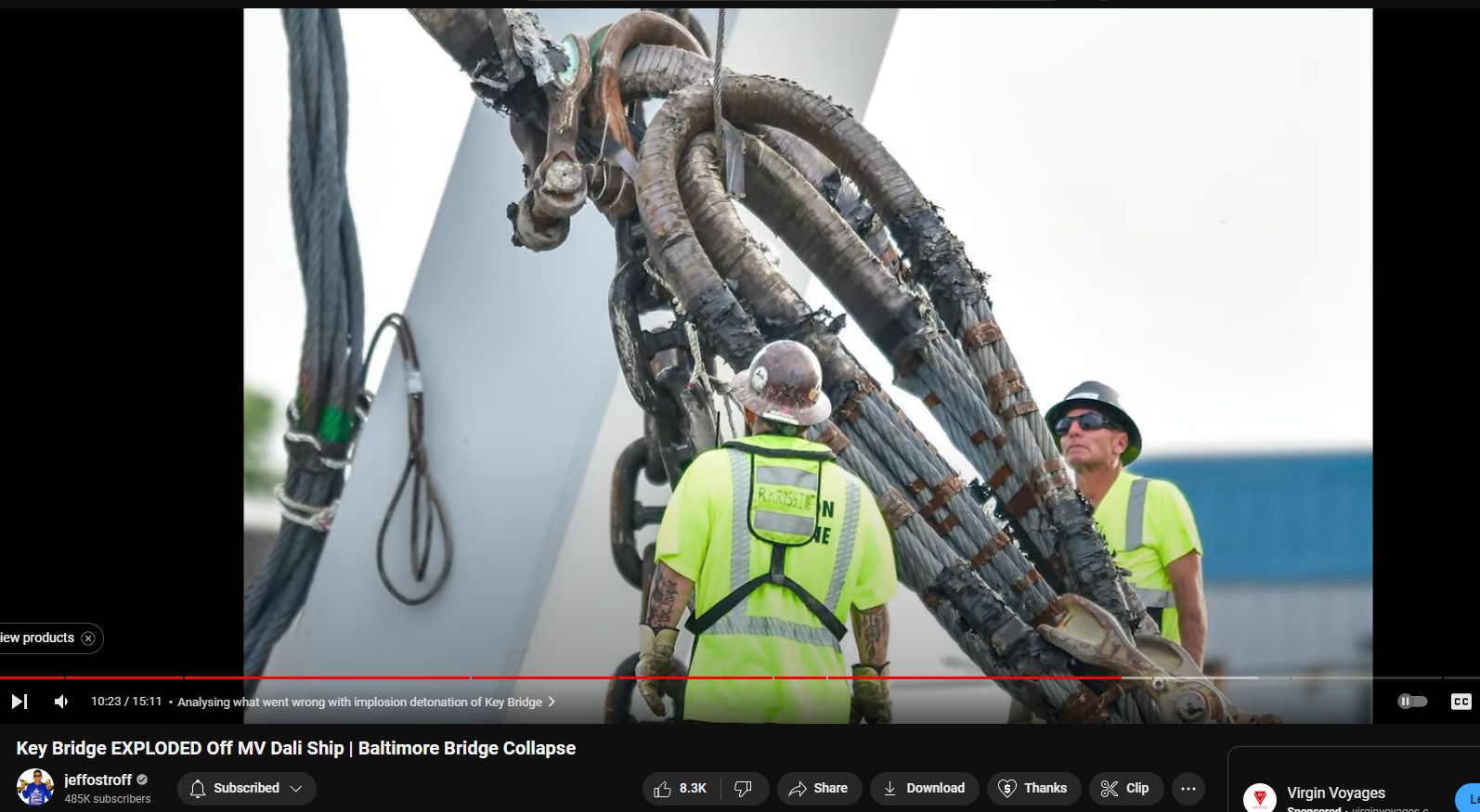

Massive Cable Supports

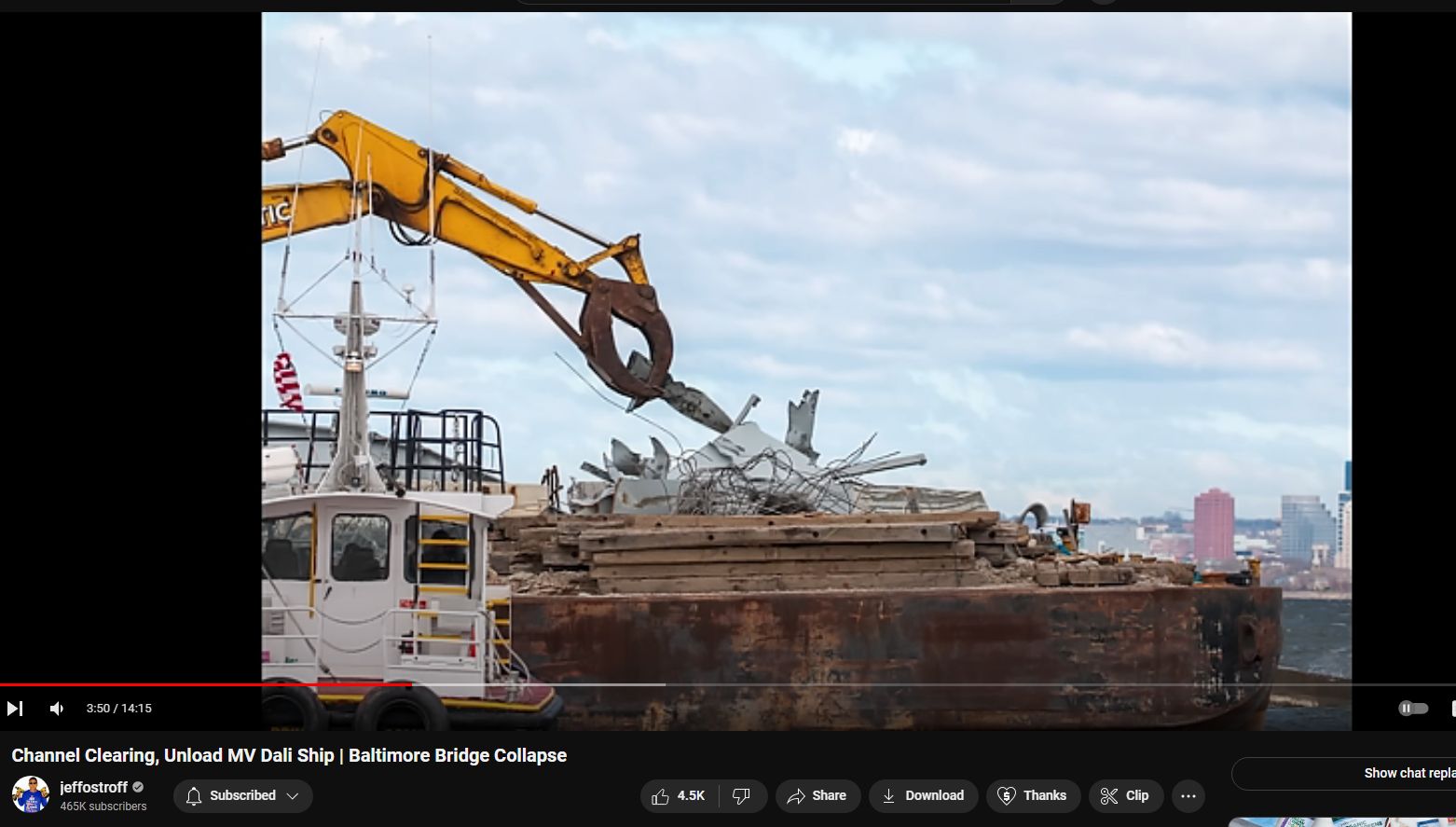

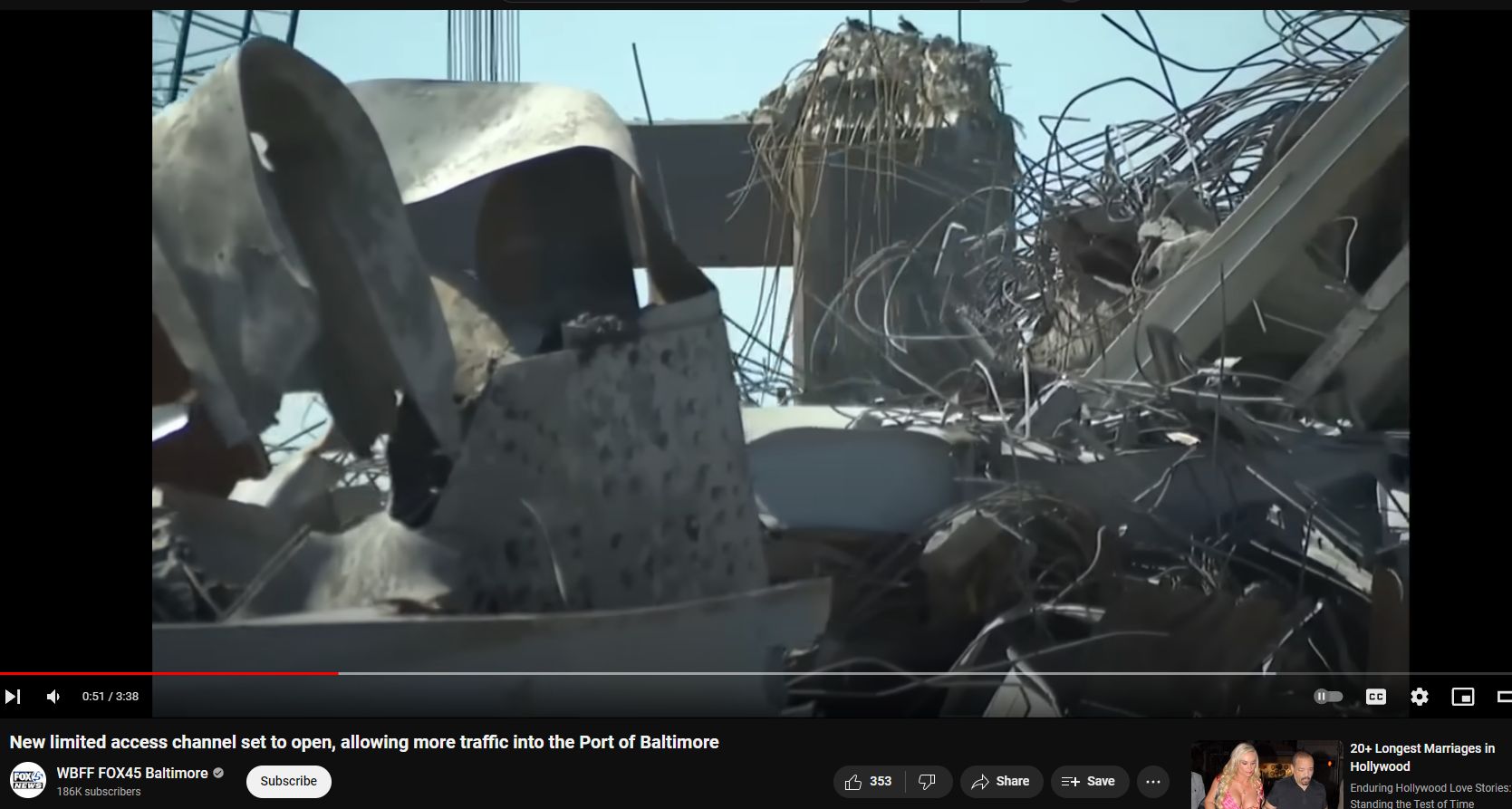

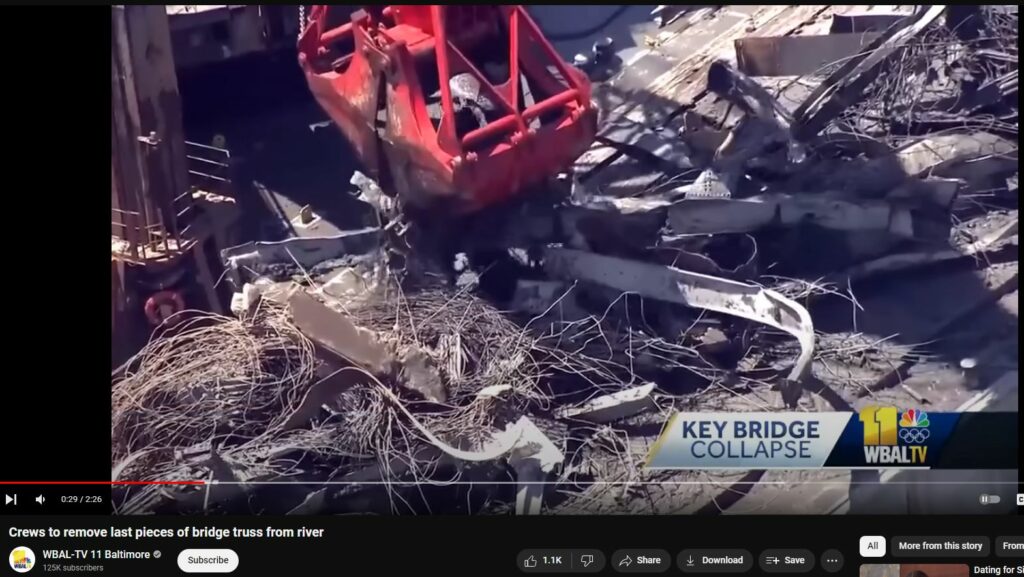

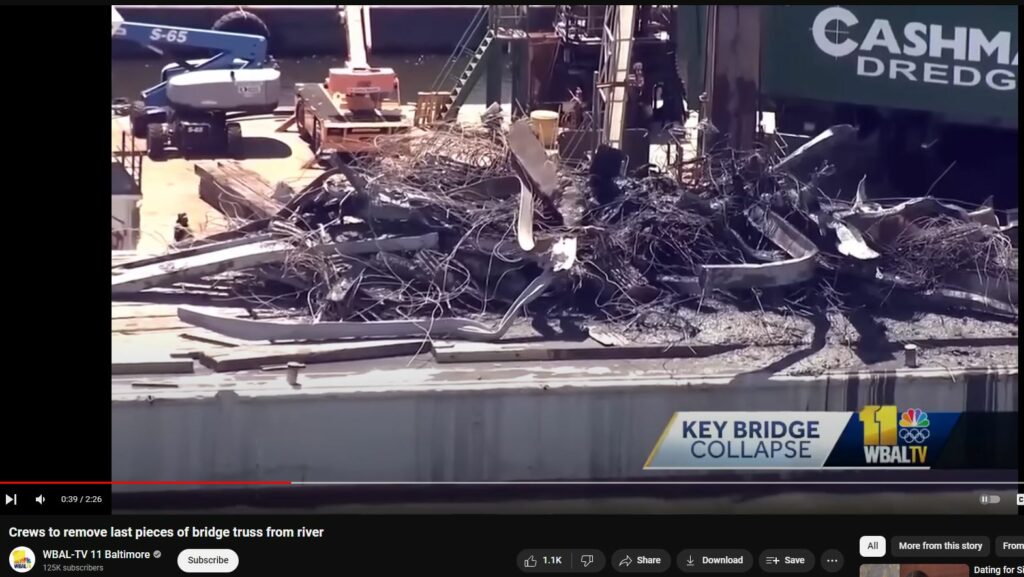

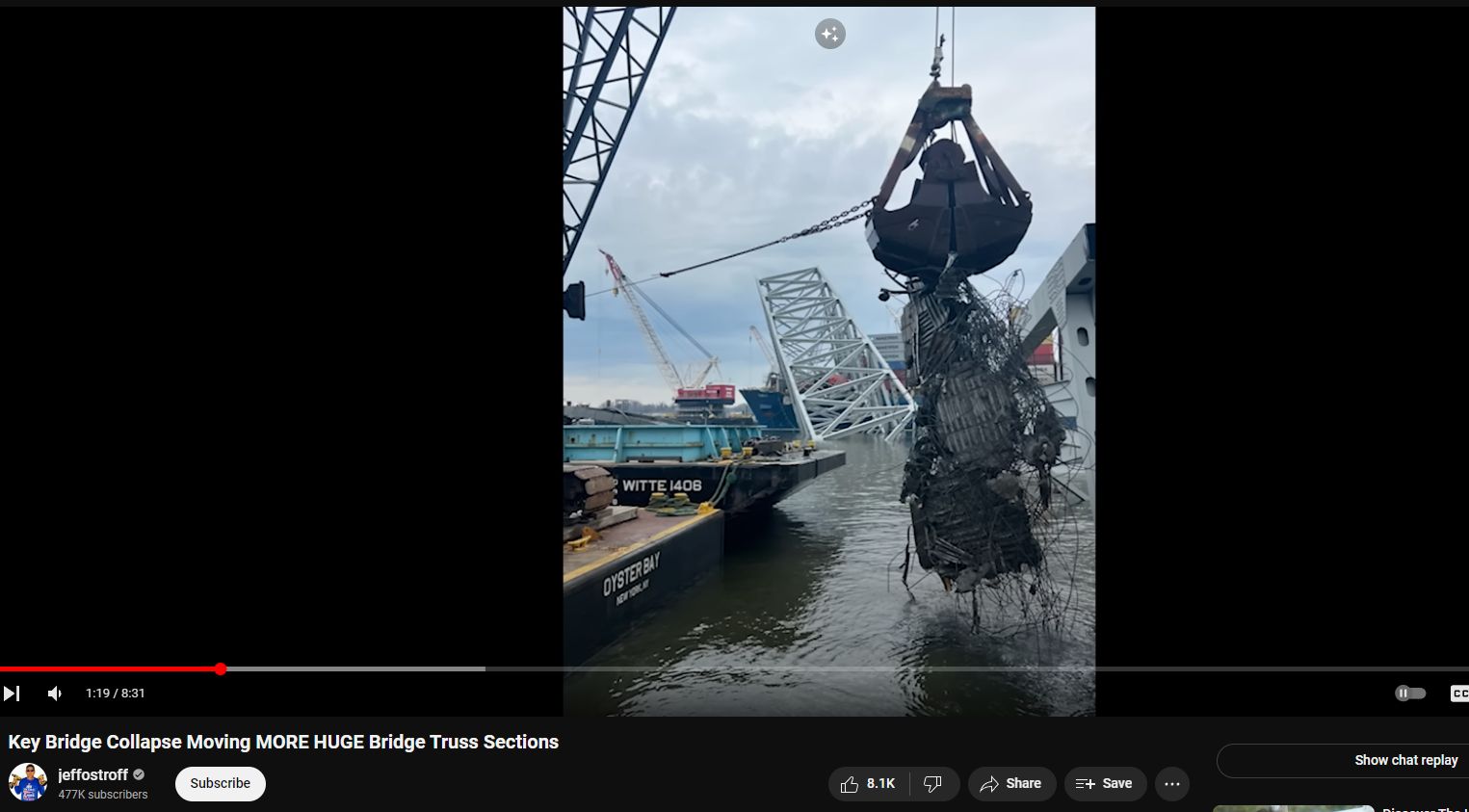

Bundles of steel support cables radically unwound and splayed, by what tremendous force?

Unwinding so radically massive steel-cable bundles that were ‘hangers’ for the roadway platform took massive energy. From where did that energy come? And how was such amount of work accomplished within moments?

How giant ropes, cables are made. https://www.youtube.com/watch?v=jntHHV10Evo

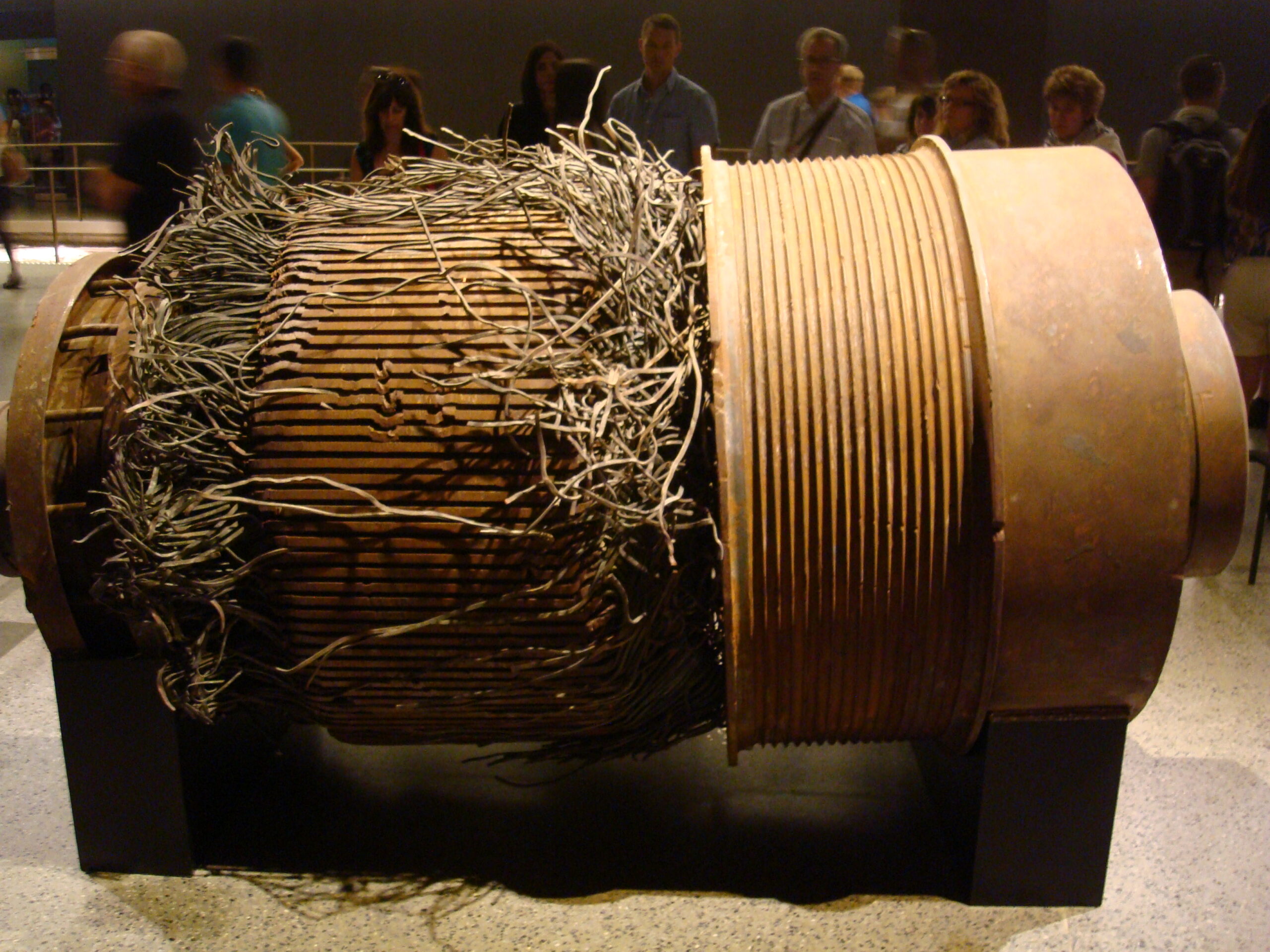

BELOW: Similar weird splaying happened to the elevator motors atop WTC on 911. All the wires’ heat-resistant wire insulation gone, and the insta-rust, as if the whole thing had become blowtorch hot.

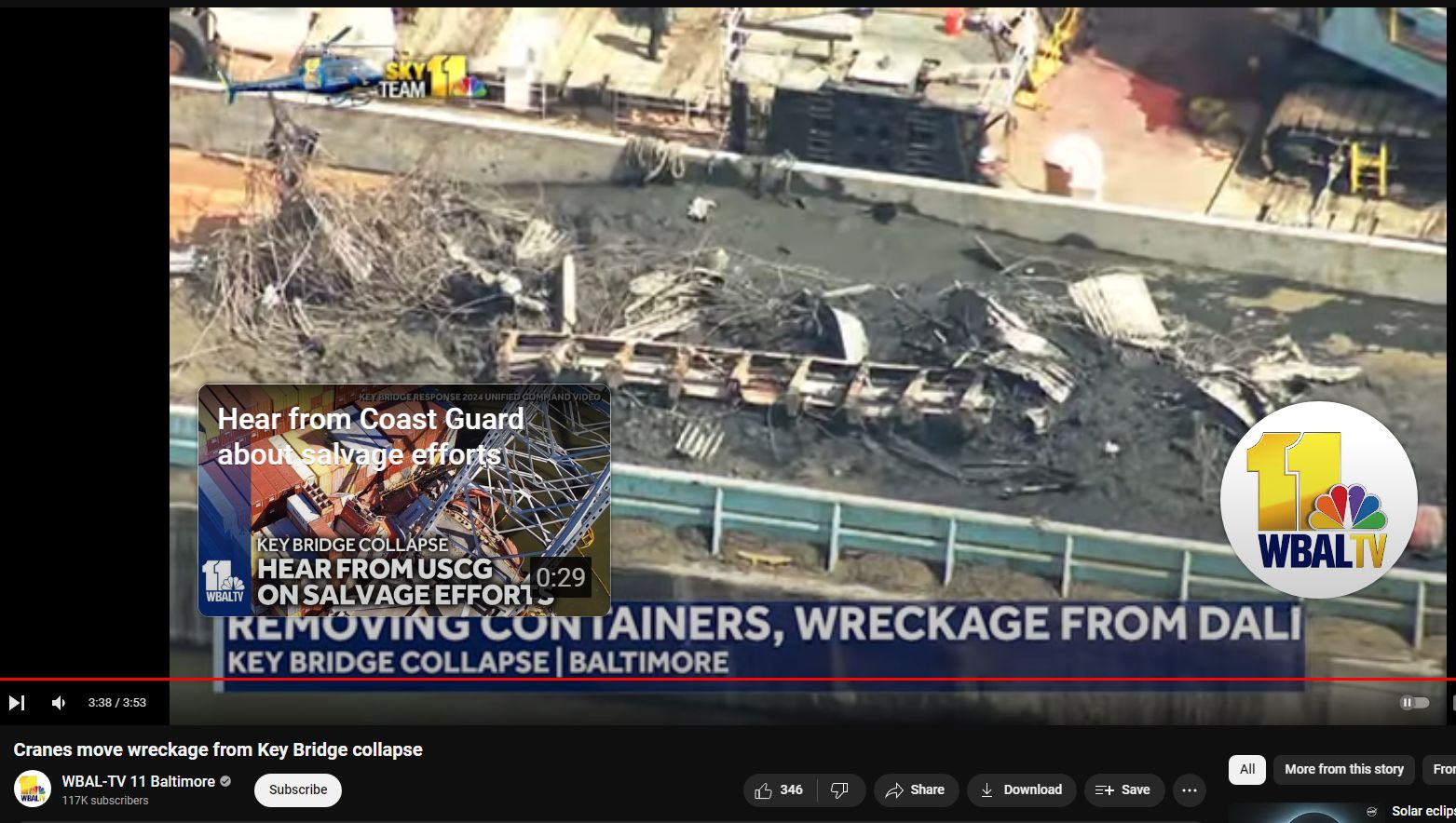

BELOW: The massive support cables, all now weirdly splayed into fine wires, as if the wire bundles had become self-repulsive due to some magneto-electrical force perhaps induced by microwave assault from Directed Energy Weapons.

BELOW: Massive support cables, all now self-splayed out from bundled finer wires.

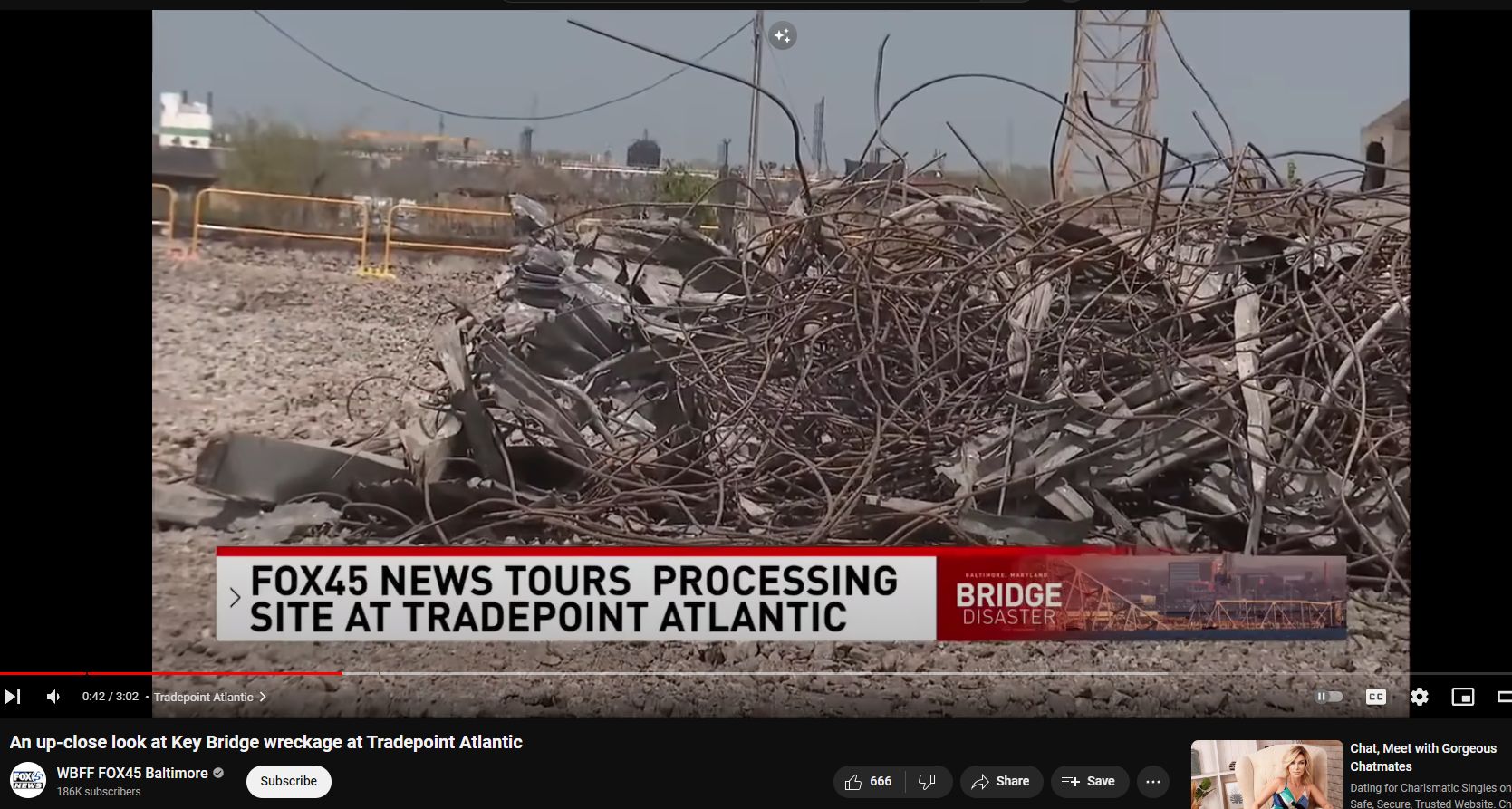

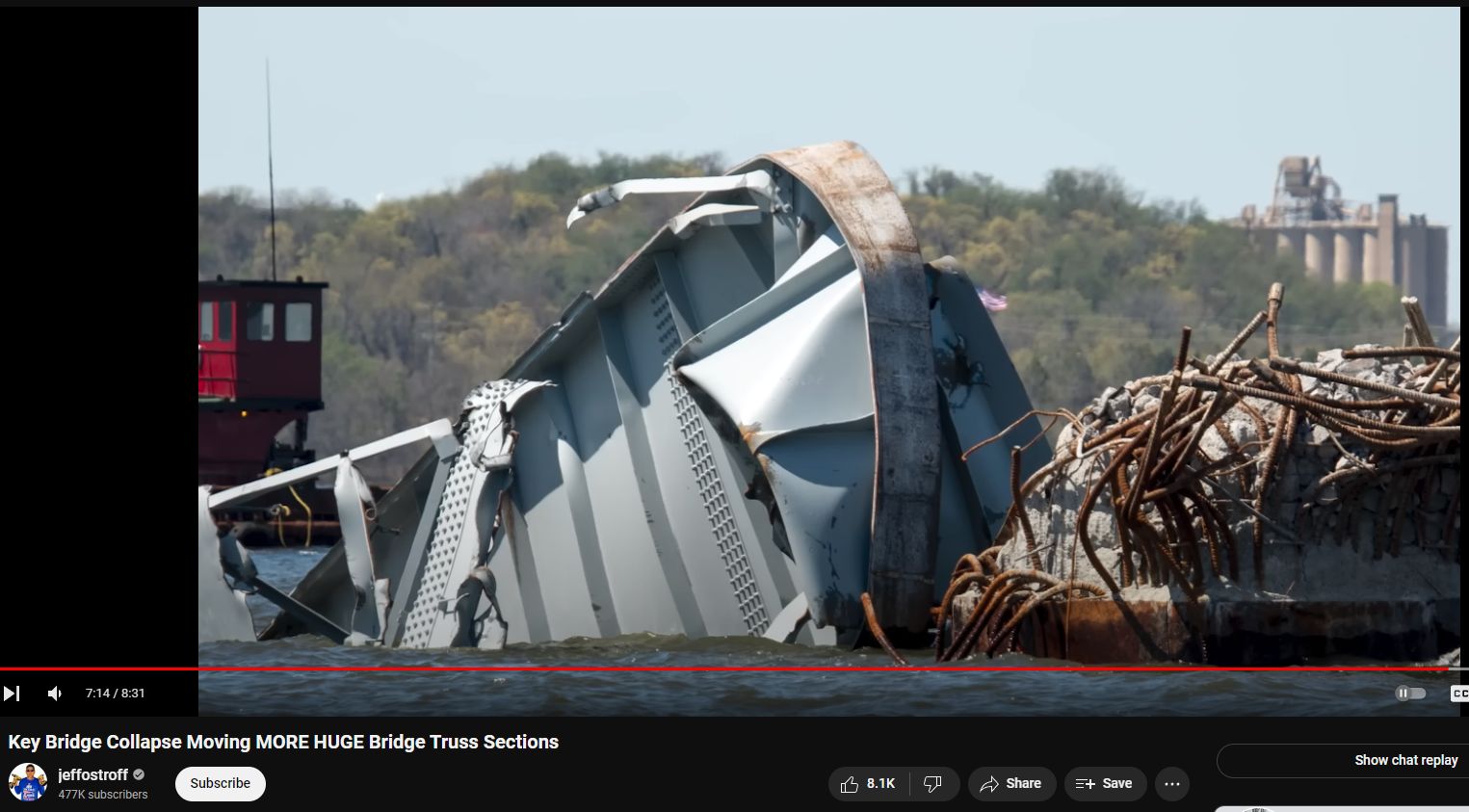

BELOW: Aftermath — this is not “rebar” but instead the splayed-out support cables. Nearly all have been found this way. The bundles were not under tension; there was no incredible spring-winding to the twisted support cables. Instead, apparently the individual strands had become repulsive to adjacent strands. Uneven presence of strong magnetic fields due to by uneven eddy currents induced by Directed Energy Weapons blast seems to perfectly explain the otherwise inexplicable evidence.

Prediction: The numerous, massive steel endpieces, the giant clasps at the ends of the cable stays — Zero of those will be recovered from the wreckage, as they are made of a different material, physically clamped/bonded onto the cable stays. Just an educated guess…along the lines of how so many vanished-as-if-never-present huge nuts and bolts are gone without a trace, similarly seemingly evaporated as practically all rivets / nuts/bolts at the ends of the many steel girders in the WTC trade towers on 911.

BELOW: Splayed-out support cables. This is not rebar which was embedded inside the roadway asphalt. This is the remains of the hanging cables which supported the roadway gridwork from the upper trusses.

REBAR

BELOW: Apparent rebar is also frenetically splayed, not bent and twisted in the direction of majority deformative force, as would be reasonably expected and seen in incidents not involving Directed Energy Weapons. Note the crossover between splayed cable stays / supports and also rebar.

See Part #29 for more RE rebar.

BELOW: Insta-rusted “Medusa-rebar”, which should be generally uniformly bent towards major moment of force but instead is “haywire” as if having been ‘impulsed’ — Directed Enery Weapons impulse imparting eddy currents unevenly would explain the powerful repulsive force instantaneously manifest amongst nearby rebars, wires, etc.

Note also the wilted structural steel that is also “impossibly” warped and distorted, as if it had been superheated by eddy currents induced by Directed Enery Weapons.

The only alternative known means to cause this kind of non-shattered, non-cracked, tightest-radius, wrinkled, warped distortion is via a blast furnace. But, no blast furnce was present. What was present, therefore, must have been Directed Enery Weapons.

When you have eliminated the impossible, whatever remains, however improbable, must be the truth. – Sir Arthur Conan Doyle, stated by Sherlock Holmes

Baltimore’s Key Bridge was taken down on-purpose. Every piece of otherwise inexplicable, anomalous evidence yields this inescapable and horrible conclusion.

BELOW: This photo provides evidence of at least some support cables not being splayed out. It also shows relative sizing.

Understanding Wound Steel Support Cables in Civil Engineering Bridge Design

In civil engineering, especially in the design of suspension and cable-stayed bridges, wound steel support cables play a crucial role. These cables, used to hang the roadway beneath steel truss structures, are integral to the bridge’s overall strength, flexibility, and durability.

The Design and Function of Wound Steel Support Cables

How Wound Steel Cables Are Made:

Wound steel cables are manufactured through a meticulous process designed to ensure maximum strength and flexibility. The process typically involves the following steps:

1. Wire Drawing: High-quality steel is drawn through a series of dies to reduce its diameter, increasing its tensile strength. This creates the individual wires that will make up the cable.

2. Stranding: The individual wires are twisted together in a helical pattern to form strands. Each strand typically consists of several wires, commonly seven or more.

3. Cable Winding: Multiple strands are then wound together in a helical pattern to form the final cable. This winding process is carefully controlled to ensure uniform tension and alignment.

Why Cables Are Wound:

The helical winding of steel wires into strands and then strands into cables is done for several key reasons:

1. Strength: The winding process distributes the load across many wires, significantly enhancing the overall tensile strength of the cable. This allows the cable to support substantial weights, such as the roadway and traffic.

2. Flexibility: Wound cables can bend and flex without breaking, accommodating the dynamic loads and movements that bridges experience due to traffic, wind, and thermal expansion.

3. Durability: The configuration of the wires in a helical pattern provides resistance to fatigue and wear, increasing the longevity of the cable.

The Role of Wound Steel Cables in Steel Truss Bridges

In steel truss bridge designs, wound steel cables are often used to hang the roadway beneath the main structural elements. These cables are anchored at both ends of the bridge and run over towers or other support structures, effectively suspending the roadway.

Energy Required to Radically Unwind Cables:

Radically unwinding a tightly wound steel cable requires an immense amount of energy due to the significant tension and stored elastic potential energy within the cable. The energy required can be conceptualized through the following factors:

1. Tensile Force: The cables are under substantial tension, often in the range of hundreds to thousands of kilonewtons. This tension must be overcome to unwind the cable.

2. Elastic Potential Energy: The helical winding stores elastic potential energy, which needs to be released. This energy is proportional to the square of the tension and the elongation of the cable.

3. Friction and Material Resistance: Unwinding involves overcoming friction between the wires and the inherent resistance of the steel material to deformation.

Estimating the exact energy required involves complex calculations considering the cable’s dimensions, material properties, and the amount of tension applied. In practical terms, this energy is very high, ensuring that such cables remain secure and intact under normal operating conditions.

Conclusion

Wound steel support cables are an essential component in the design of suspension and cable-stayed bridges, providing the necessary strength, flexibility, and durability to safely support roadways. Their intricate manufacturing process and the principles of tension and elasticity make them incredibly robust and reliable. Understanding these elements highlights the ingenuity and precision required in civil engineering to create structures that withstand the test of time and the forces of nature.