“This was a trillion-dollar costly event, ongoing, and yet all culpable persons remain unnamed, kept totally anonymous, with some reportedly having been slyly ‘escaped’ from the country! There is, in fact, zero publicly-verifiable evidence that any genuine Captain, Pilots or Crew ever existed; was DALI a remote-controlled ghost-ship on kamikazee mission from its outset? No waves nor sounds at all were recorded nor reported by any nearby persons nor cameras. No interviews exist with supposed survivors; “family and friends” etc interviews reveal ‘dupers-delight’ micro-facial-expressions with other hallmarks suggestive of fraud. Rampant is the extremely suspicious damage with blatantly visible, verifiable anomalies totally inexplicable (and ignored) by official theory or story. Grand payola galore is already underway with loads more coming. This is another audacious yet sublime crime, militarized from gov to salvage to rebuild. There was no rescue skiff on scene as required by OSHA. No horn blasts from ship warned of imminent collision. The ship departed despite dire electrical problems, illegal at any time and even more highly unusual in the cold, dark night-time (part #94, first ‘after-sundown departure’ in two years). Criminal was this manufactured event, through and through, and that’s before considering the absurdly high number of other anomalies including the complicit, worthless, ‘kept-pet’ mass-media…”

Part #91 adapted from a video comment

Index . Oddity List . Official Story . Summary

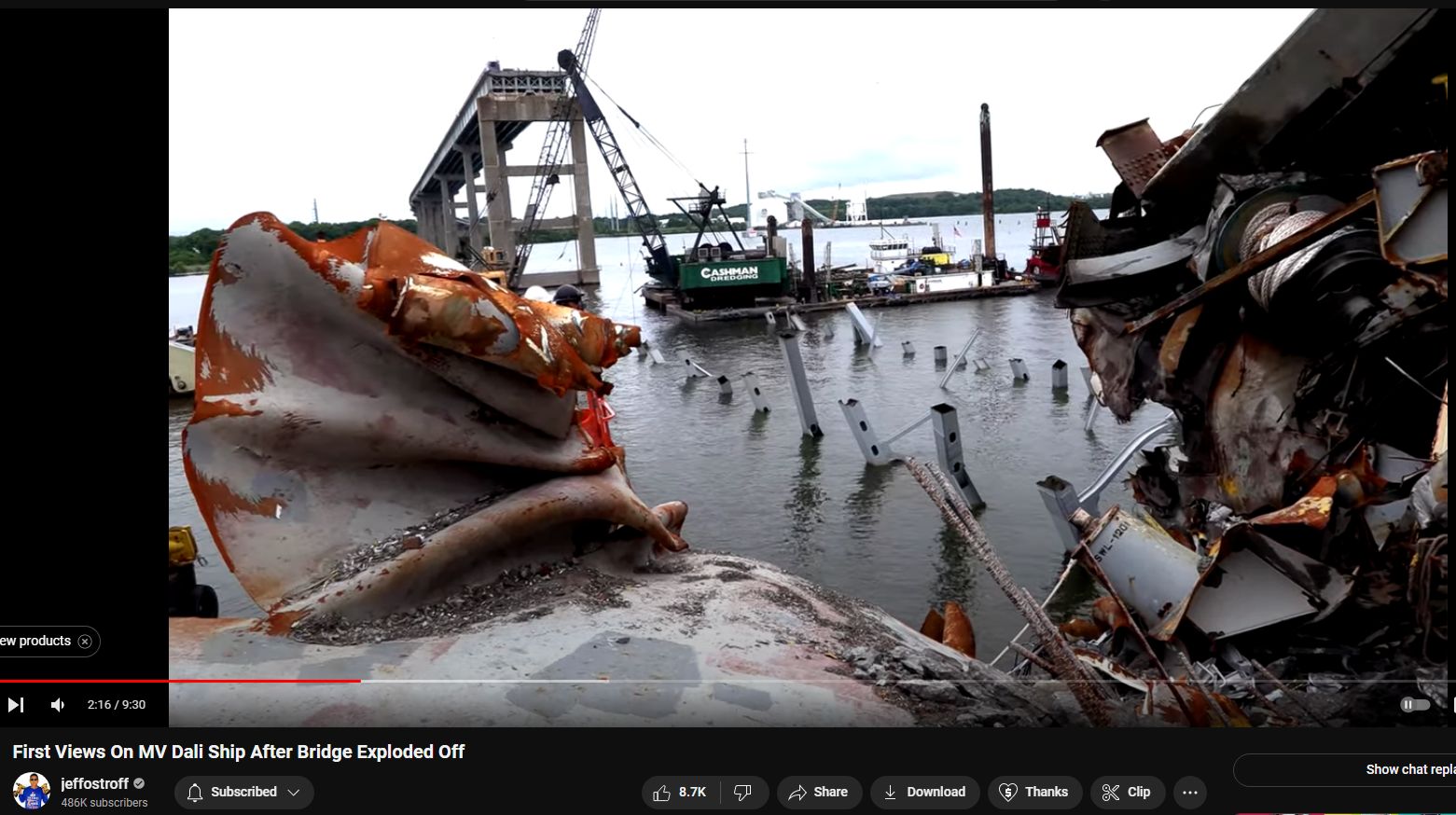

South Pillar multi-modal damage by Directed Energy Weapons

DEWs superheat metals via induced eddy currents causing blast-furnace-like melting and consequent distortions and faliures

See Part #14 – “Impossibly” gouged and pierced Thick Steel Hull. Destroyed South Pillar.

See also Part #16 which examines the incredibly splayed cable stays / supports. Steel wires and steel rebar (and electrical motors in case of WTC in NYC on 911) apparently suffer similar effects when hit with Directed Energy Weapons.

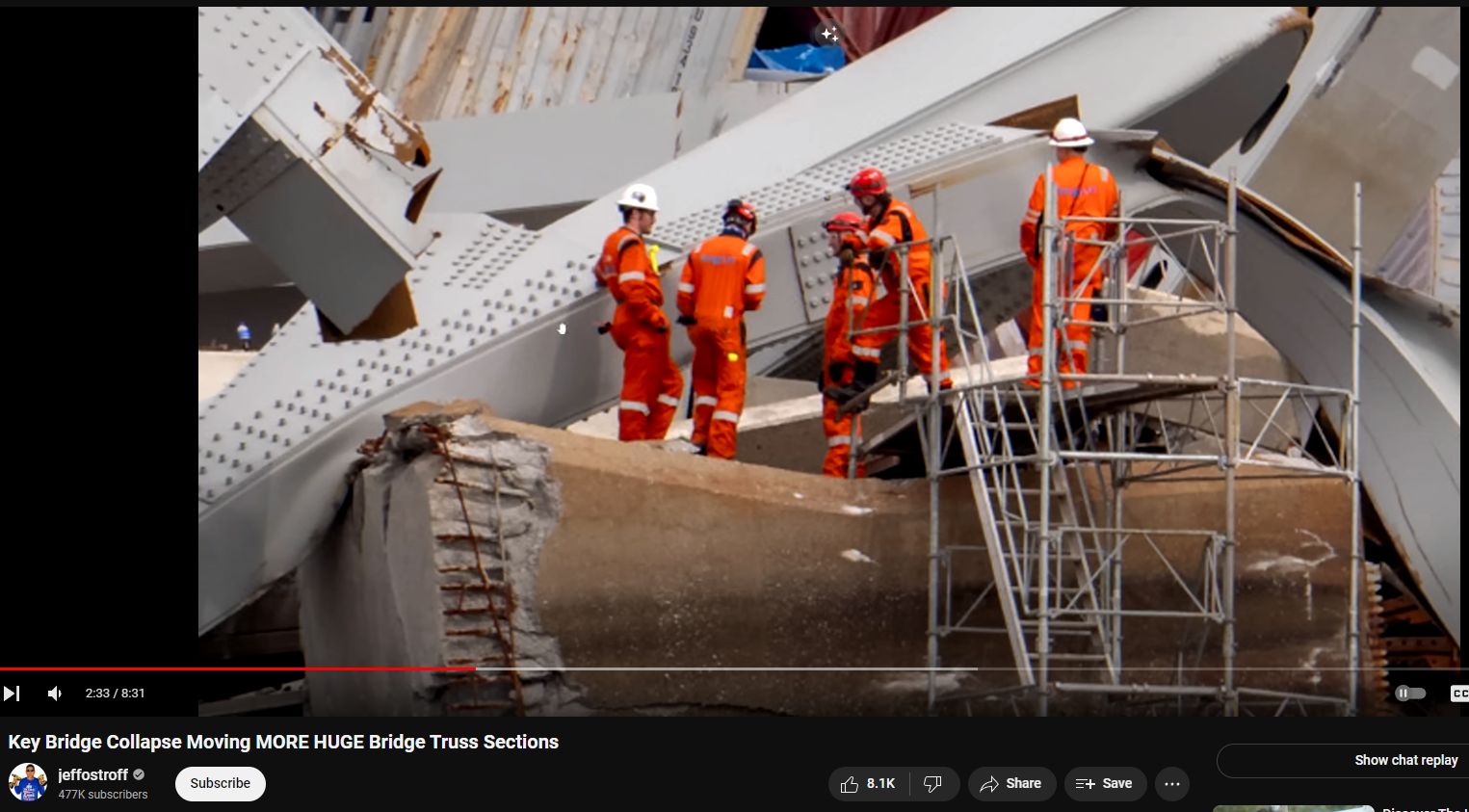

BELOW: Notice the insta-rusted rebar that had been recently encased inside the South Pillar concrete; all that rusting happened after the concrete was broken away and the rebar cooled after having been superheated by Directed Energy Weapons, per wikipedia: “In corrosion engineering terms, when designed correctly, the alkalinity of the concrete protects the steel rebar from corrosion“. Also, notice how the main girder in this image seems “molten” over the left-edge of the pillar. Notice also the fractured / shattered appearnce of the secondary girder attaching just above, and compare that to the amazing molten/wilting (and delaminating!) of the same steel girder drooping over the right-edge of the South Pillar. Directed Energy Weapons yield amazingly otherworldly evidence, impossible to explain by any physical loading or effect.

BELOW: Notice the equally-amazing “sidewalk smooth” literal “cut” of the concrete at the left-edge (showing internals) of South Pillar. Amazing.

BELOW: Sidewalk-smooth “cut” of the concrete. A blunt-force massive magnitude strike would crackle and crumble and leave incredibly jagged and extremely uneven the concrete, as shown in all building and other concrete structure collapses. That here in presence of a Directed Energy Weapons attack exists such a smooth cut is amazing evidence of not-normal energies having been employed in the intentional take-down of Baltimore’s Key Bridge. It’s too bad Jeff Ostroff does not yet have ‘eyes to see’, mind to delve nor consider the far more likely cause of Directed Energy Weapons. (Ostroff exhibits hope, because he did post a video delving into, essentially: ‘What The Hell Is That FBI Signal Jamming Vehicle Doing Atop the standing southern approach?!’)

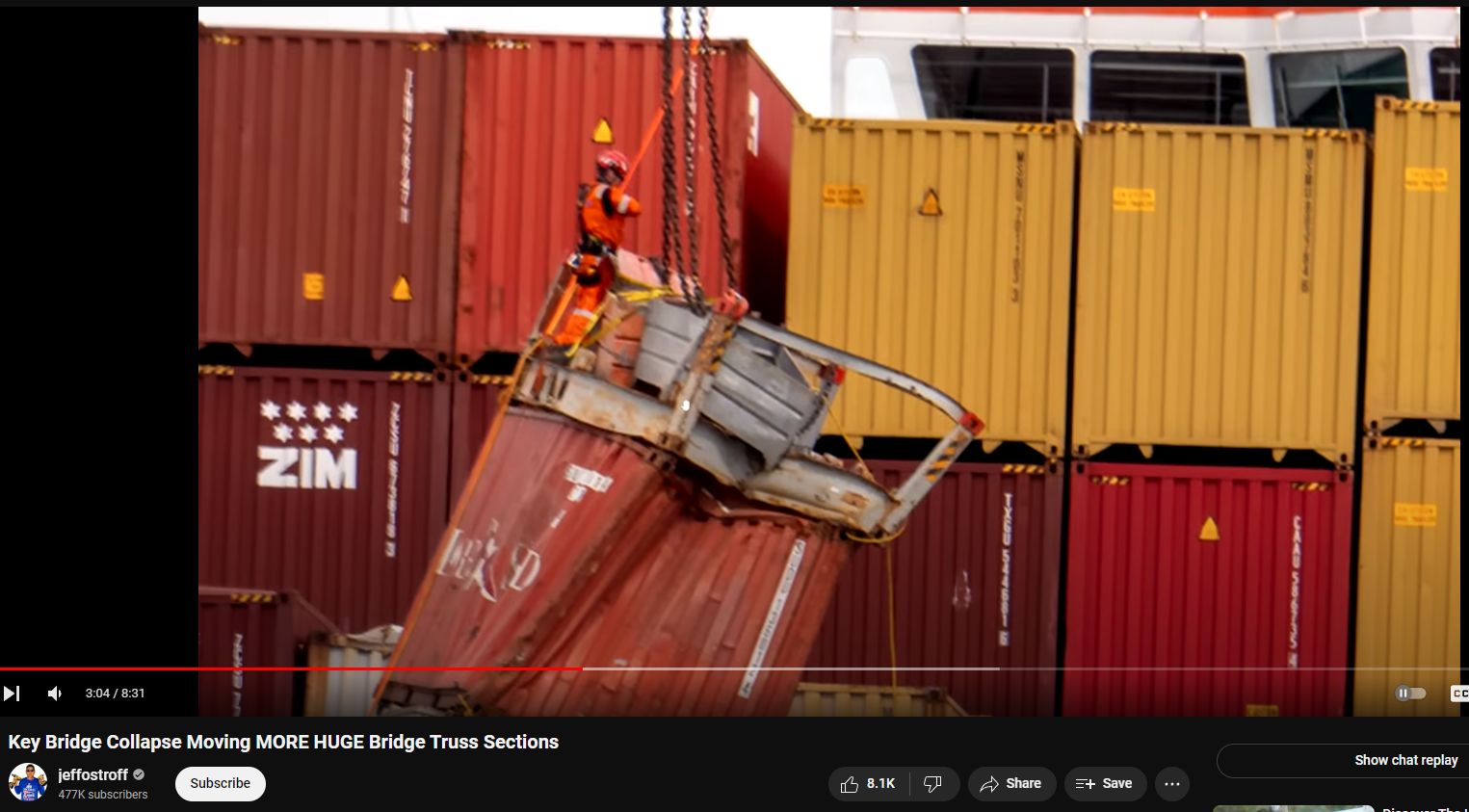

The “crushing” of the containers is something seen at other DEW attack sites. It is more of a wilting and even of an “implosion” speculated to be caused by eddy current “skin effect” on thinner materials causing self-magnetization attractions and repulsions, directly and nearly instantaneously causing the “crumpling” effect (thousands of car hoods and rooves in Tianjin, China DEW attack, for example). Most likely the only energy that contacted and affected most of these “crumpled” or “imploded” or “crushed” containers was of the directed type. Clearly, for some containers actualy physical damage was caused by bridge trusswork, force of steel causing ripped and shredding of container, etc, but hardly all.

DEWs superheat metals

BELOW: Incredibly interesting in this image is how the ‘container grabber’ mechanism was also wilted and distorted by the Directed Energy Weapons. Any physical force powerful enough to have bent and wilted that steel would have long before sheared that entire mechanism right off the top of the container. What shocks me the most is how nearly everyone who sees these incredible, otherworldly anomalies remains silent and likely absolutely aloof to the reality of causation…and the pickle we’re consequently all in with presumably misogynistic and self-admittedly eugenecidal “global elites” having control over weapons of such secrecy, anonymity and power.

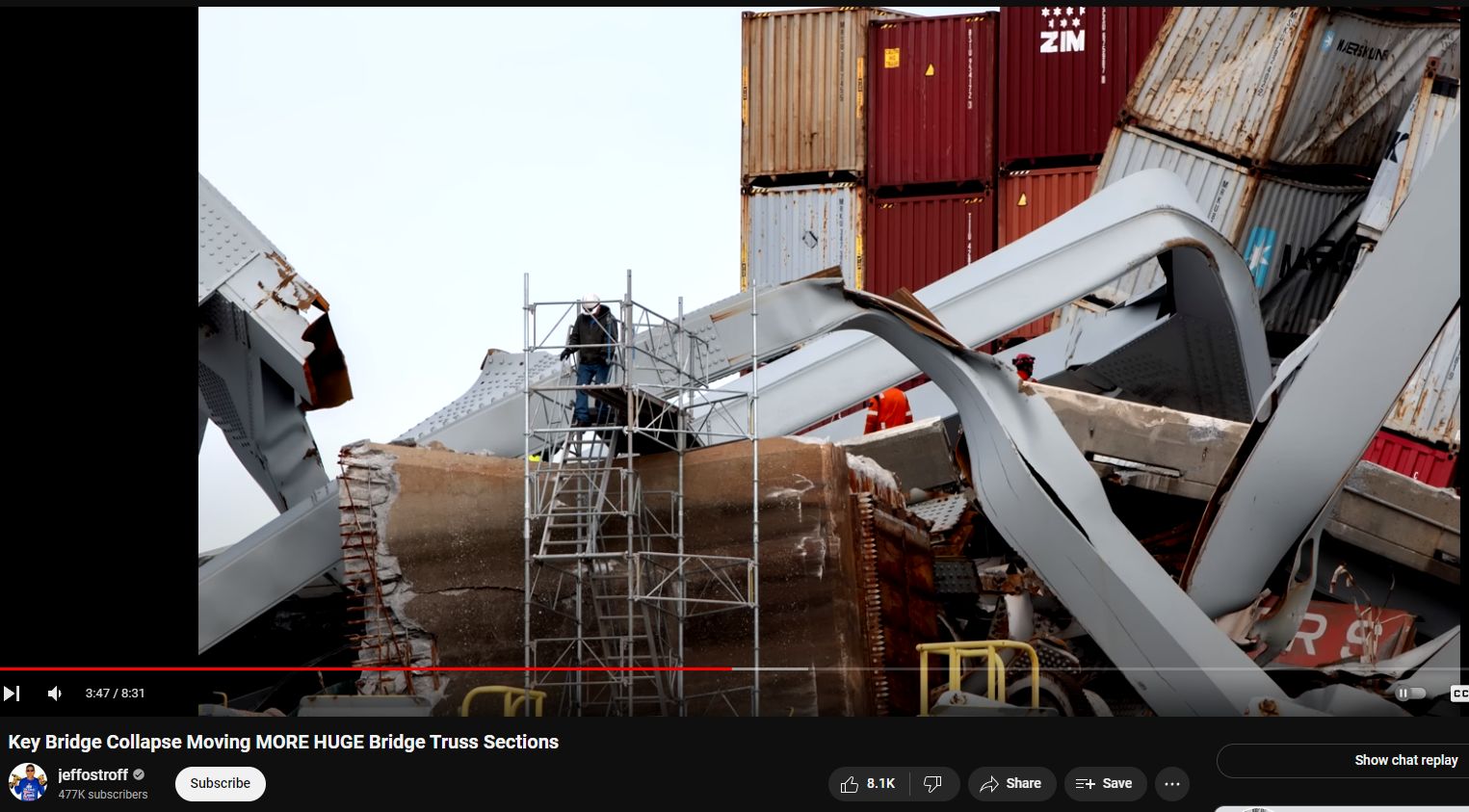

BELOW: Note the insta-rusted rebar and also insta-rust on the steel girders. Notice also the noodle-like bending of the most massive and strongest structural steel available, all without fracturing, shattering or even stress/radius-cracking (and, in most cases the paint is not even cracked!). Only two means are know that can cause this kind of deformation: One is a blast furnace; the other is Directed Energy Weapons. Similar splitting or “delaminating” appears all over the WTC 911 evidence, too. Steel does not do this under any known physical loading conditions; additional energy must be applied, and in this case that additional energy appears to have been of the directed kind. Notice also the insta-rusted support / weight-distribution steel anchor plate that is attached to what was formerly the top of the South Pillar. Curiously, the North Pillar never had any such plate. Two pillars built at same time, same purpose, same companies, same loading, same structure — why the big difference in design?

BELOW: Steel cracks and shatters when overstressed, it does not warp and wilt (crack-free!) like hot taffy unless exposed to blast furnace or heating via Directed Energy Weapons. That crack-free fan-folding of structural steel (whether the bridge or the ship) to image-left is alone anomalous enough to warrant special investigation into cause, but the economic force driving clean-up rush is overpowering. — https://www.youtube.com/watch?v=_n7_-34qeOk

See also Part #22

The Role of Alkalinity in Reinforced Concrete: A Rust-Resistant Fortress

Introduction

Reinforced concrete is a cornerstone of modern construction, prized for its strength and durability. Central to its longevity is the interplay between concrete and steel rebar, where the concrete’s natural alkalinity plays a crucial role in protecting the rebar from rusting. Understanding this chemical relationship is key to appreciating why reinforced concrete structures can withstand the test of time.

The Basics of Reinforced Concrete

Reinforced concrete combines the high compressive strength of concrete with the high tensile strength of steel rebar. This synergy allows for the construction of robust structures capable of enduring significant stress and environmental conditions. However, the steel rebar’s vulnerability to rusting poses a significant threat to the integrity of these structures.

The Protective Alkalinity of Concrete

Concrete is inherently alkaline, with a pH typically around 12 to 13. This high alkalinity environment is crucial for protecting the steel rebar embedded within it. The alkalinity of concrete induces the formation of a passive oxide layer on the surface of the steel, which acts as a barrier against rust (oxidation).

How Alkalinity Prevents Rusting

1. **Formation of the Passive Layer**: When steel rebar is placed in fresh concrete, the high pH environment causes a thin, stable layer of iron oxide to form on the rebar’s surface. This passive layer is impervious to water and oxygen, effectively preventing the onset of rust.

2. **Maintaining the Alkaline Environment**: As long as the concrete remains intact and uncracked, the high pH environment is maintained, and the passive layer remains effective. This is why the quality of the concrete mix and proper curing practices are vital.

3. **Chloride Ion Protection**: Chloride ions, commonly found in de-icing salts and seawater, are a significant threat to reinforced concrete. They can penetrate concrete and break down the passive layer, leading to rust. The alkalinity of concrete helps resist chloride ion penetration to some extent. However, in environments with high chloride exposure, additional protective measures, such as the use of corrosion inhibitors or protective coatings, may be necessary.

The Importance of Mix Design and Maintenance

The composition and quality of the concrete mix are critical in ensuring long-term alkalinity and, consequently, the protection of rebar. Key factors include:

– **Water-Cement Ratio**: A low water-cement ratio reduces the porosity of concrete, limiting the ingress of harmful substances like chlorides.

– **Supplementary Cementitious Materials**: Materials like fly ash, slag, and silica fume can enhance concrete’s durability and maintain its alkalinity.

– **Proper Curing**: Ensuring that concrete is adequately cured helps achieve optimal strength and durability, maintaining its protective properties.

Dealing with Carbonation

Over time, carbon dioxide from the air can penetrate concrete and react with calcium hydroxide to form calcium carbonate, a process known as carbonation. This lowers the pH of concrete, potentially compromising the passive layer on the rebar. Preventive measures include:

– **Adequate Cover Depth**: Ensuring sufficient concrete cover over the rebar to slow down carbonation.

– **Use of Sealants and Coatings**: Applying protective sealants or coatings to concrete surfaces to reduce carbonation rates.

Innovations in Reinforced Concrete

Modern advancements aim to enhance the rust resistance of reinforced concrete. These include:

– **Epoxy-Coated Rebar**: Applying an epoxy coating to rebar provides an additional barrier against corrosion.

– **Stainless Steel Rebar**: Using stainless steel, though more expensive, offers superior corrosion resistance.

– **Corrosion Inhibitors**: Adding chemical inhibitors to the concrete mix can help protect the rebar from chloride-induced corrosion.

Conclusion

The alkalinity of concrete is a fundamental factor in the durability of reinforced concrete structures. By maintaining a high pH environment, concrete ensures the formation and preservation of a protective oxide layer on the rebar, preventing rust. Proper mix design, curing, and protective measures are essential to sustaining this alkaline environment and extending the life of reinforced concrete structures. As technology advances, innovations continue to improve the rust-resistant properties of reinforced concrete, ensuring its continued dominance in the construction industry.