“This was a trillion-dollar costly event, ongoing, and yet all culpable persons remain unnamed, kept totally anonymous, with some reportedly having been slyly ‘escaped’ from the country! There is, in fact, zero publicly-verifiable evidence that any genuine Captain, Pilots or Crew ever existed; was DALI a remote-controlled ghost-ship on kamikazee mission from its outset? No waves nor sounds at all were recorded nor reported by any nearby persons nor cameras. No interviews exist with supposed survivors; “family and friends” etc interviews reveal ‘dupers-delight’ micro-facial-expressions with other hallmarks suggestive of fraud. Rampant is the extremely suspicious damage with blatantly visible, verifiable anomalies totally inexplicable (and ignored) by official theory or story. Grand payola galore is already underway with loads more coming. This is another audacious yet sublime crime, militarized from gov to salvage to rebuild. There was no rescue skiff on scene as required by OSHA. No horn blasts from ship warned of imminent collision. The ship departed despite dire electrical problems, illegal at any time and even more highly unusual in the cold, dark night-time (part #94, first ‘after-sundown departure’ in two years). Criminal was this manufactured event, through and through, and that’s before considering the absurdly high number of other anomalies including the complicit, worthless, ‘kept-pet’ mass-media…”

Part #91 adapted from a video comment

Index . Oddity List . Official Story . Summary

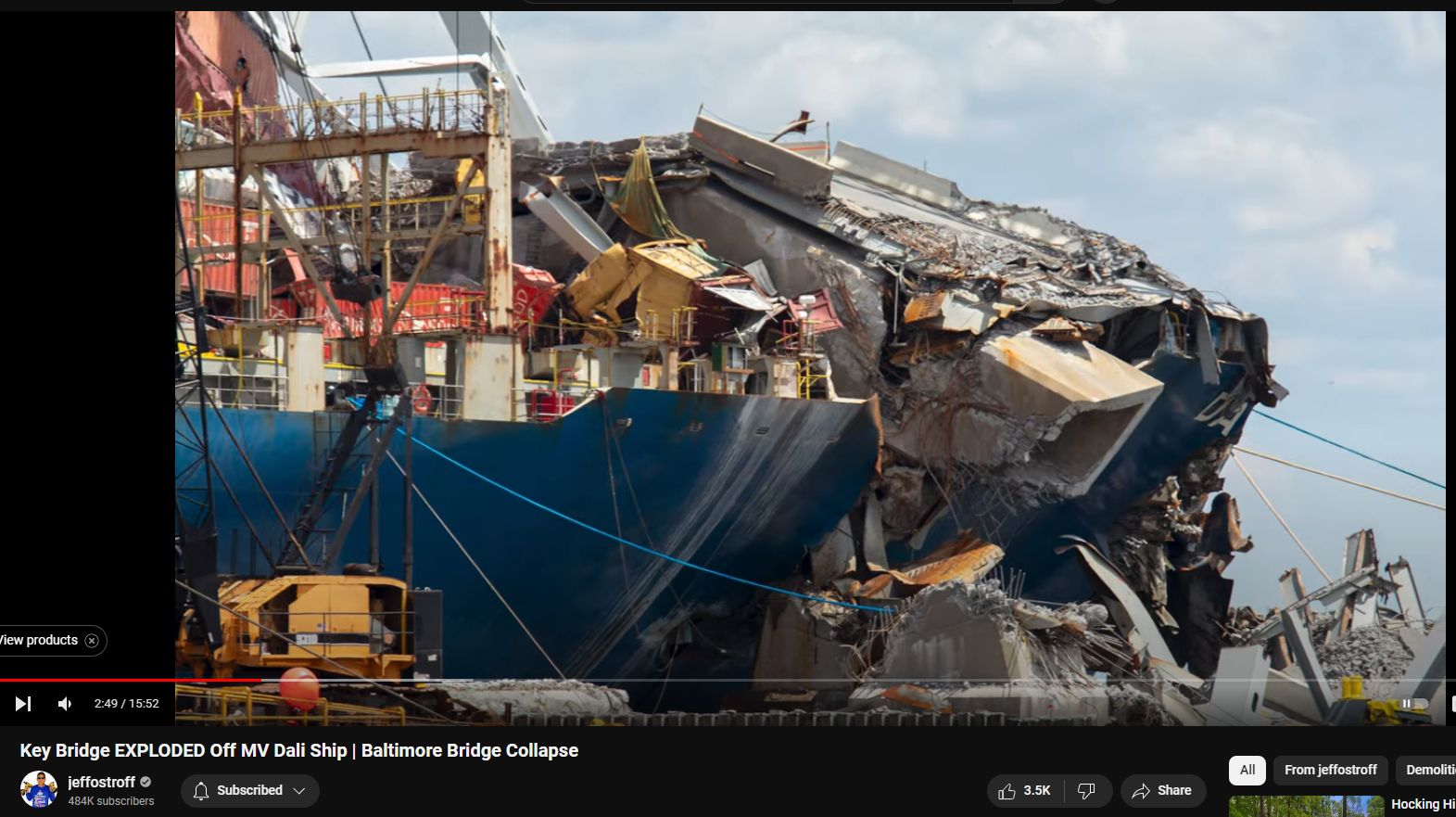

Steel never cuts through steel

Dali’s Impossibly Gouged and Stabbed Steel Hull

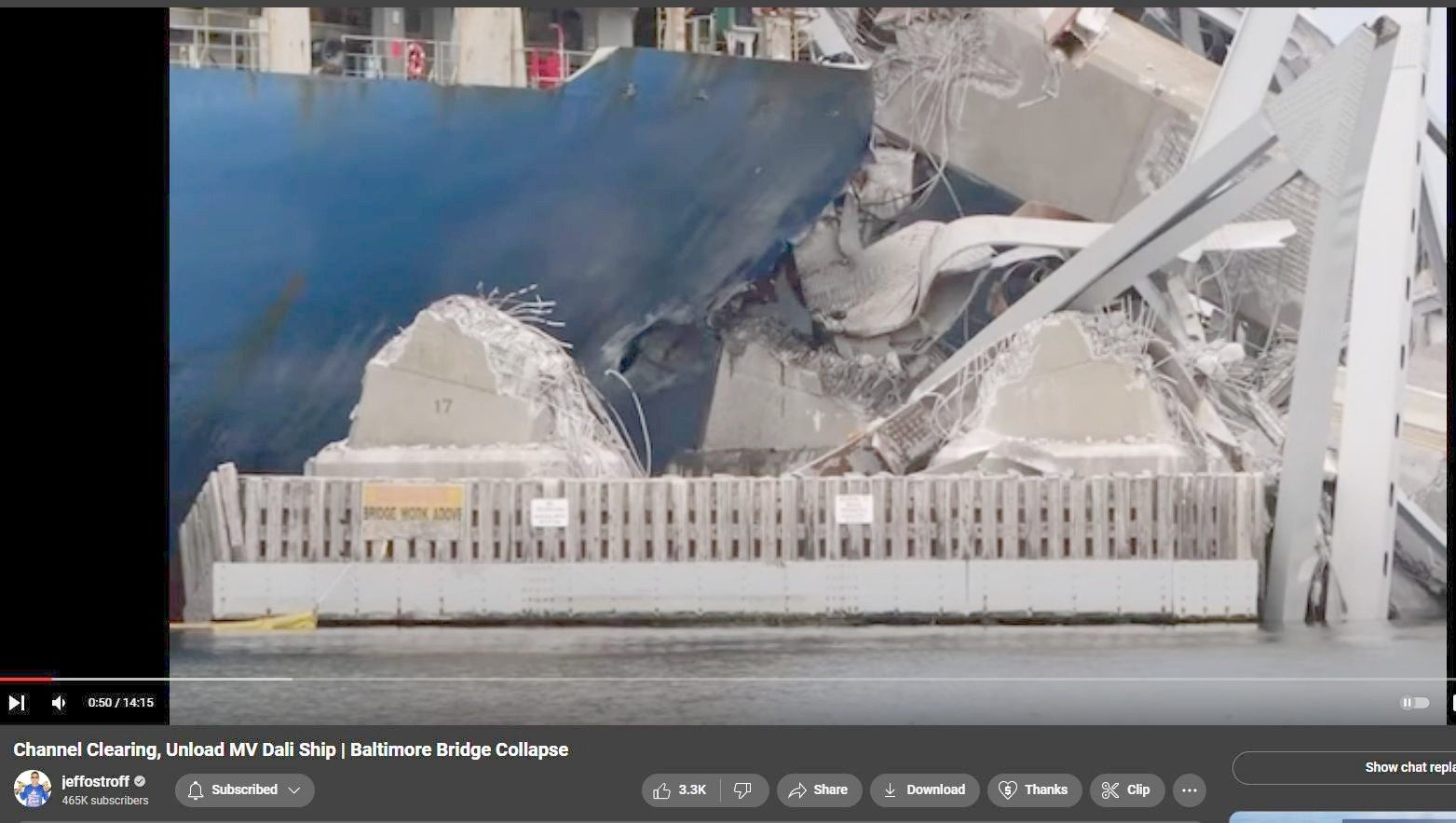

See Part #14 – “Impossibly” gouged and pierced Thick Steel Hull. Destroyed South Pillar.

In original night footage, the DALI never even tilts or lists to starboard as it is getting gashed-open down nearly its entire side, at the strongest part of the hull, and in the direction of greatest resistance to being gashed open!

Also, what punctured that gaping hole? There is no debris, pillar or girder there to have caused such amazing damage. It almost looks like a blaster-thru LASER hole or something…

Also, what could have so perfectly sliced that massive concrete pillar without any crumbling or chunking-away or even any rebar left protruding every which way as we see all other rebar does?

Look at those warped, wilted, taffy-like distortions in the structural steel girders. Perfectly expected if the steel had been superheated, totally inexplicable otherwise.

What a comically mounting mountain of anomalies…

What “gaping hole” ? The one They’ve been hiding so carefully behind barges and shadows and omissive camera angles. Lightening the image gamma reveals the massive “missile hole”.

Also which such prideful containment of contaminants from the event outset, how convenient all that paint gushed down the side in perfect place to aid the concealment.

BELOW: Here’s an earlier image, then very rare, without the distracting paint recently poured —

“If the hull had been superheated by Directed Energy Weapons and thus softened, molten, then suddenly all the “anomalous” evidence makes complete and total sense.”

More from the video comments:

“Shame on you for not bringing up anomalies such as how steel girder could possibly cut through steel hull, exactly like sword cutting through armored car. CONSPIRA has a 62-part series all and only about the anomalies galore plaguing all traditional explanations of HOW.”

Understanding Material Hardness: Rockwell, Mohs, Knoop, and Vickers Scales

Material hardness is a critical property in engineering, manufacturing, and material science. It defines a material’s resistance to deformation, scratching, and indentation. Several scales and tests measure hardness, each providing unique insights into a material’s characteristics. Let’s delve into the Rockwell hardness test, the Mohs scale, Knoop hardness, and Vickers hardness to understand how hardness is rated and the implications of these measurements.

Rockwell Hardness

The Rockwell hardness test measures the depth of penetration of an indenter under a large load compared to the penetration made by a preload. The Rockwell scale is divided into multiple scales, each suitable for different materials and conditions. For instance, the Rockwell C scale (HRC) is commonly used for harder materials like steel and provides a direct hardness number without requiring complex calculations.

Mohs Scale of Mineral Hardness

The Mohs scale, developed by Friedrich Mohs in 1812, is a qualitative ordinal scale that ranks minerals based on their ability to scratch one another. The scale ranges from 1 (talc) to 10 (diamond). Each mineral can scratch those below it on the scale but can be scratched by those above it. For example, a material rated at 7 on the Mohs scale (such as quartz) can scratch any material rated 6 or lower but will be scratched by any material rated 8 or higher.

Knoop Hardness

The Knoop hardness test uses a diamond indenter with an elongated, rhombic-based pyramidal shape. It measures the size of the indentation left by the indenter under a specific load. The Knoop hardness number (KHN) is calculated based on the applied load and the dimensions of the indentation. This test is particularly useful for brittle materials or thin coatings due to the minimal penetration depth of the indenter.

Vickers Hardness

The Vickers hardness test employs a diamond pyramid indenter with an angle of 136 degrees between opposite faces. The test measures the diagonal lengths of the indentation to calculate the Vickers hardness number (VHN). The Vickers test is versatile, applicable to a wide range of materials, and can be used for both macro and micro hardness testing.

Rating Material Hardness

Material hardness is rated by subjecting the material to controlled conditions of load and measuring the resulting indentation or scratch. The values obtained from tests like Rockwell, Mohs, Knoop, and Vickers provide a quantitative measure of hardness. Higher numbers indicate harder materials, which are more resistant to deformation, scratching, and indentation.

Interaction of Materials with Different Hardness

A fundamental principle in material science is that a material can only be scratched, gouged, or punctured by another material that is harder. This principle is evident in the Mohs scale, where a higher-ranked material can scratch any lower-ranked material. Conversely, materials of the same hardness cannot scratch each other. This principle has practical applications in various industries, from tool manufacturing to construction.

Steel vs. Steel: The Impossibility of Cutting Through

Considering this principle, a steel girder cannot cut through a steel hull of equal or greater hardness. Both materials, having similar hardness, will resist deformation when in contact with each other. Even if they possess similar strength, the equal hardness means neither can scratch, gouge, or puncture the other. This is why, in practical scenarios, cutting or penetrating steel typically requires a material that is significantly harder or specialized cutting tools that apply mechanical or thermal processes to facilitate the cut.

Conclusion

Understanding the hardness of materials is crucial for their application in various fields. The Rockwell, Mohs, Knoop, and Vickers scales provide comprehensive methods to measure and rate material hardness. The fundamental concept that materials of equal or lesser hardness cannot scratch or penetrate harder materials underscores the importance of selecting appropriate materials for specific applications. This principle ensures that in construction and manufacturing, materials are chosen and applied in a manner that maximizes durability and performance.

“I live 5 miles away from the collapse site. I was watching Minorcan Mullet’s live stream and heard the big boom sound from my backyard. Sound carried downriver for sure.”