“This was a trillion-dollar costly event, ongoing, and yet all culpable persons remain unnamed, kept totally anonymous, with some reportedly having been slyly ‘escaped’ from the country! There is, in fact, zero publicly-verifiable evidence that any genuine Captain, Pilots or Crew ever existed; was DALI a remote-controlled ghost-ship on kamikazee mission from its outset? No waves nor sounds at all were recorded nor reported by any nearby persons nor cameras. No interviews exist with supposed survivors; “family and friends” etc interviews reveal ‘dupers-delight’ micro-facial-expressions with other hallmarks suggestive of fraud. Rampant is the extremely suspicious damage with blatantly visible, verifiable anomalies totally inexplicable (and ignored) by official theory or story. Grand payola galore is already underway with loads more coming. This is another audacious yet sublime crime, militarized from gov to salvage to rebuild. There was no rescue skiff on scene as required by OSHA. No horn blasts from ship warned of imminent collision. The ship departed despite dire electrical problems, illegal at any time and even more highly unusual in the cold, dark night-time (part #94, first ‘after-sundown departure’ in two years). Criminal was this manufactured event, through and through, and that’s before considering the absurdly high number of other anomalies including the complicit, worthless, ‘kept-pet’ mass-media…”

Part #91 adapted from a video comment

Index . Oddity List . Official Story . Summary

Was the South Pillar really just “stacked blocks”, made to be knocked-over in a mega-event?

Zero rebar at the “impossibly” clean-cuts (at multiple locations) in the concrete leg (and other parts) of the South Pillar all indicate an initial design-to-fail, no?

It sure looks like it was made to be easily knocked-over in some future mega-event, no?

Yes, understandably we could count on the massive loading weight of the multiple-kiloton steel truss bridge to basically hold everything in place via extreme downward force under gravity. But, what about when a container ship plows into the side of the pillar, or underneath its base?

According to the “impossible” evidence, it was either that — a “rely-upon-gravity / design-to-yield”, or there exists and was employed some Directed Energy Weapon that can (apparently) clean-slice concrete cleanly in hot-knife-through-butter-like fashion and leave zero rebar visible or splayed-out willy-nilly in every which way (as seen in so much other evidence). Interesting to note that the rebar that is present elsewhere (including encased inside the concrete) has also been insta-rusted, most likely due to superheating via eddy currents induced by Directed Energy Weapons.

Peggy Hall outed the Pelosi Crime Family as having been in-power / in-charge during the design and construction of the FSK Bridge. It’s not so ‘far-fetched’ to imagine a conspiracy and scheming.

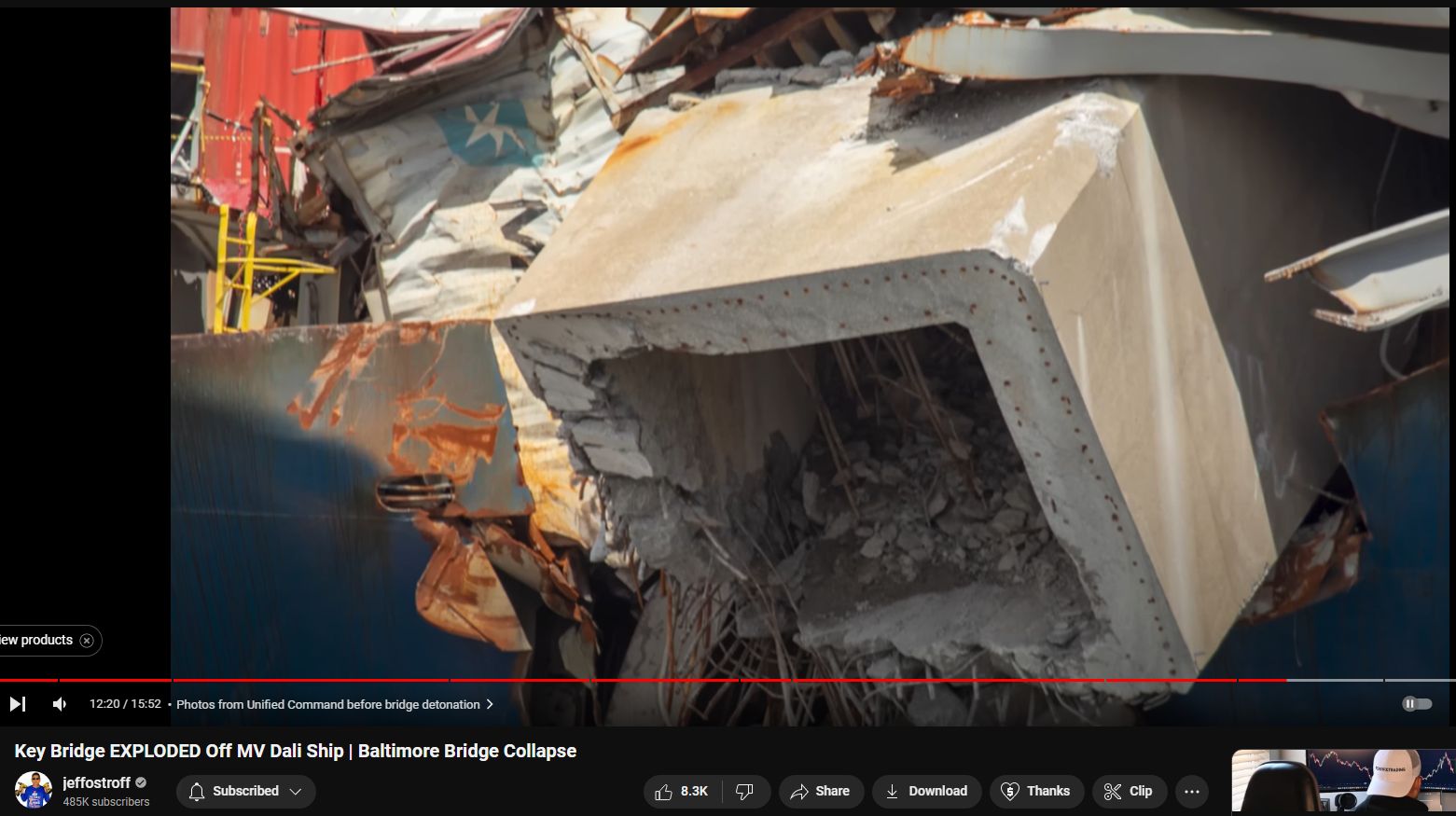

BELOW: Boosted gamma to lighten midrange. Notice the “impossible” bottom of that hanging pillar leg … clean-cut and zero rebar! “Impossible” unless it was designed that way, like some kind of “lego-bridge”. It would seem that there should be many whiskers of rebar flailing out of that clean-cut surface, and the surface should not be clean-cut. How were these two anomalies possibly produced (even if accounting for Directed Energy Weapons), if not designed- and built-in from construction of the bridge?

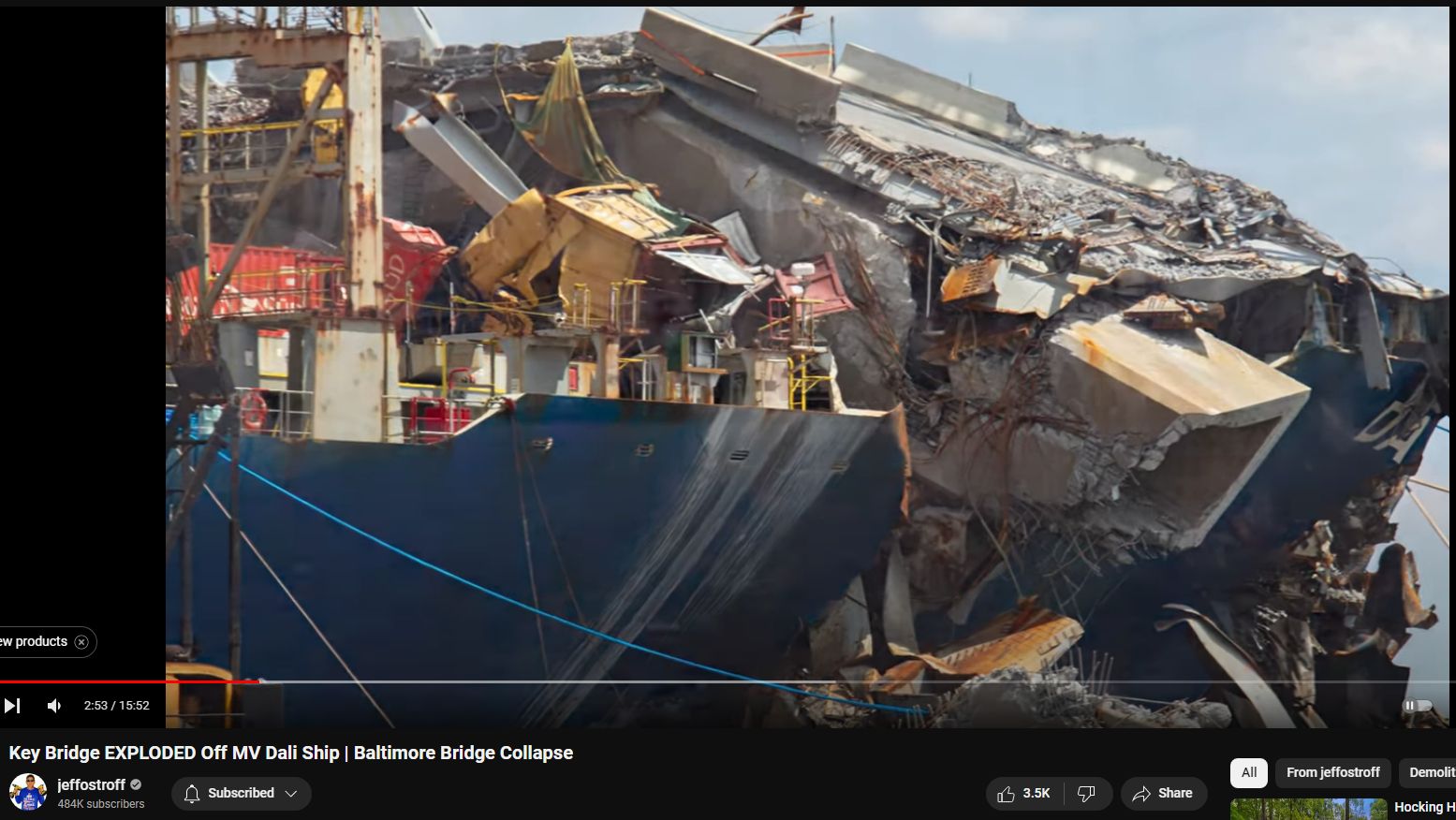

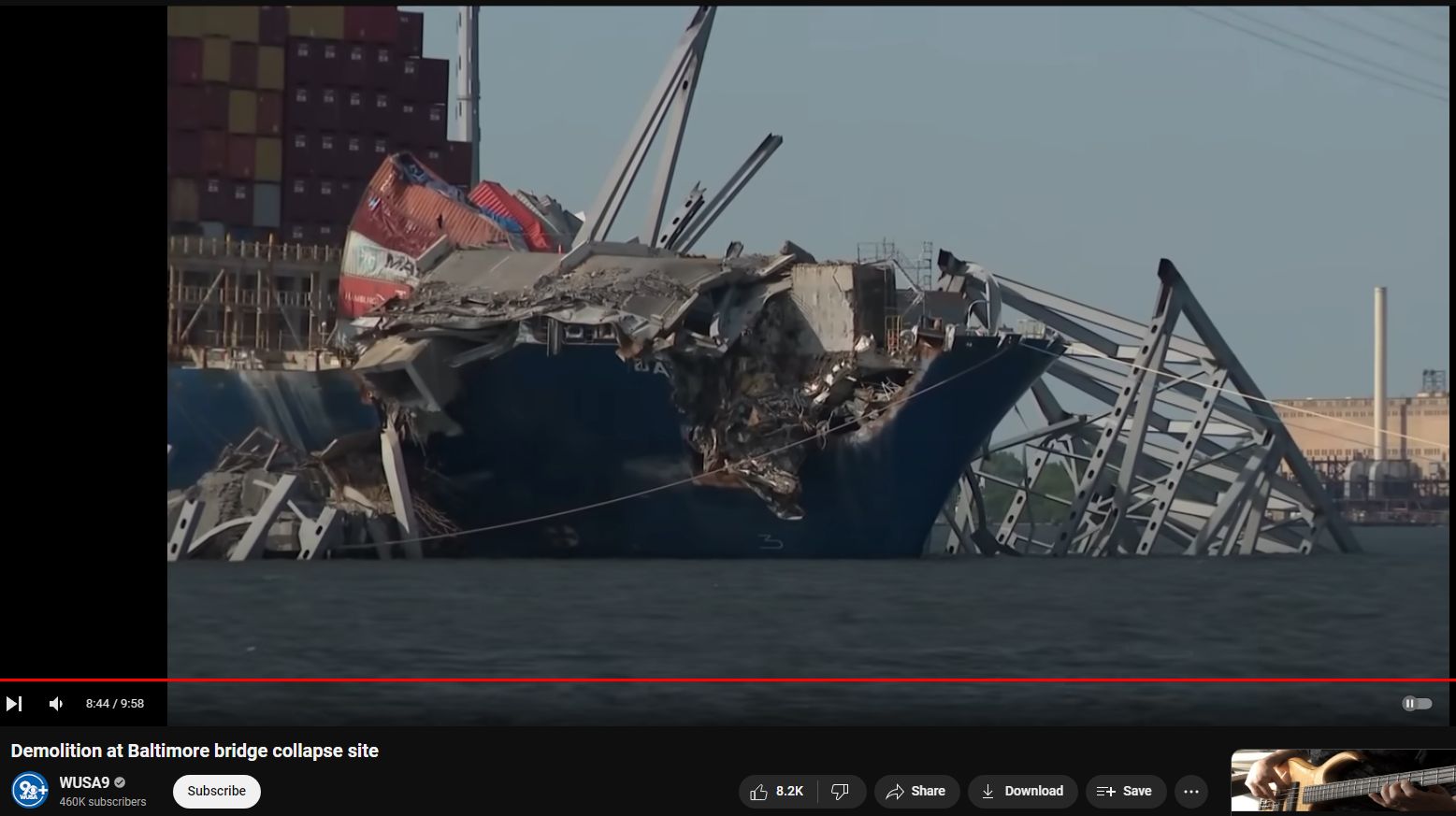

BELOW: Update 16 May — Another view later in same video shows what appears to be cut-off rebar embedded in the hollow concrete leg. Someone commented that the pillar had been cut with a “diamond wire saw”. Regardless, interesting that some rebar is insta-rusted and some apparently unaffected. Don’t miss the impossibly wilted and warped steel girders, and the amazingly imploded shipping containers.

More evidence of South Pillar being merely ‘stacked blocks, designed-to-fail in some future mega-event’

See Part #29 for more on the rebar analysis

BELOW: Though this massive chunk contains rebar (curiously insta-rusted, probably due to superheating via eddy currents induced by microwaves in Directed Energy Weapons) it has that “impossibly” clean-cut concrete, as if the entire massive block were just sitting there, stacked, ready to be knocked-over in some mega-event…

BELOW: It appears as if the DALI’s steel hull had been melted due to superheating by Directed Energy Weapons and then gravity and friction did the rest. Where is that massive, gouged-out slab of steel hull? Probably dustified.

The Importance of Massive Concrete Support Pillar Design for Steel Truss Bridges: A Civil Engineering Perspective

The design and construction of steel truss bridges is a marvel of modern civil engineering, combining aesthetics, functionality, and durability. Central to the stability and longevity of these structures are the massive concrete support pillars, which provide the necessary foundation to bear immense loads and withstand various environmental stresses. This blog explores the significance of these pillars, the role of rebar within them, and the principles behind their design.

The Role of Concrete Support Pillars

Concrete support pillars serve as the backbone of steel truss bridges, transferring loads from the bridge deck down to the ground. These pillars must be robust enough to handle:

1. **Dead Loads**: The weight of the bridge structure itself.

2. **Live Loads**: Variable weights such as vehicles, pedestrians, and dynamic forces from wind or seismic activity.

3. **Environmental Loads**: Forces exerted by environmental factors such as earthquakes, floods, and temperature fluctuations.

The design of these pillars is critical to ensuring the bridge’s safety, stability, and longevity. They must be meticulously planned to handle the anticipated loads and resist various forms of stress.

The Need for Rebar in Concrete Pillars

Concrete, while strong in compression, is relatively weak in tension. To overcome this limitation, steel reinforcement bars, or rebar, are embedded within the concrete. Rebar enhances the tensile strength of the concrete, allowing it to better withstand the diverse stresses imposed on bridge support pillars.

The integration of rebar in concrete pillars offers several benefits:

1. **Increased Strength**: Rebar significantly boosts the tensile and compressive strength of concrete, allowing the pillars to support greater loads and resist cracking.

2. **Enhanced Durability**: Rebar helps in maintaining the structural integrity of the concrete over time, even under harsh environmental conditions.

3. **Flexibility in Design**: The use of rebar allows engineers to design more slender and aesthetically pleasing pillars without compromising on strength and stability.

Design Considerations for Concrete Support Pillars

Designing concrete support pillars for steel truss bridges involves several key considerations to ensure their effectiveness and durability:

1. **Load Analysis**: Engineers must perform detailed load analysis to determine the types and magnitudes of forces the pillars will encounter. This includes considering both static and dynamic loads.2. **Material Selection**: The choice of concrete and rebar must match the environmental conditions and expected loads. High-performance concrete and corrosion-resistant rebar are often used for greater durability.

3. **Rebar Placement and Spacing**: Proper placement and spacing of rebar within the concrete are crucial. Rebar must be positioned to effectively counteract tensile forces and prevent cracking.

4. **Foundation Design**: The support pillars must be anchored to a solid foundation capable of transferring loads to the ground. This may involve deep foundations such as piles or caissons, depending on soil conditions.

5. **Environmental Considerations**: The design must account for potential environmental impacts, including corrosion from saltwater, freeze-thaw cycles, and seismic activity.

Case Study: The Use of Concrete Pillars in Modern Bridges

A prime example of effective concrete support pillar design can be seen in the construction of the Millau Viaduct in France. This cable-stayed bridge, one of the tallest in the world, relies on massive concrete piers to support its steel truss structure. The pillars, some exceeding 300 meters in height, are reinforced with extensive rebar to handle the enormous forces exerted by the bridge and environmental conditions.

The success of the Millau Viaduct underscores the importance of meticulous design and the integration of rebar in concrete support pillars. It highlights how modern civil engineering techniques can create safe, durable, and visually stunning infrastructure.

Conclusion

The design of massive concrete support pillars for steel truss bridges is a critical aspect of civil engineering that ensures the safety, stability, and longevity of these structures. The use of rebar embedded within the concrete is essential for enhancing tensile strength and durability. By understanding the principles behind load analysis, material selection, rebar placement, and environmental considerations, engineers can create support pillars that effectively bear the loads imposed by modern bridges, paving the way for innovative and resilient infrastructure.

As we continue to push the boundaries of bridge design, the integration of advanced materials and techniques will further enhance the performance and longevity of concrete support pillars, ensuring the continued safety and reliability of our transportation networks.